Technology

Italian facility

.jpg)

Product Lines

OE |

AFTERMARKET |

| Industrial engines | Off Road engines |

| Gardening engines | Street Bike engines |

| Off Road engines | Scooter engines |

| Street Bike engines | Go Kart engines |

| Snow-mobile engines | Marine engines |

| Go Kart engines | PWC engines |

| Scooter engines | |

| Air Compressors | |

| Marine engines | |

| Pumps |

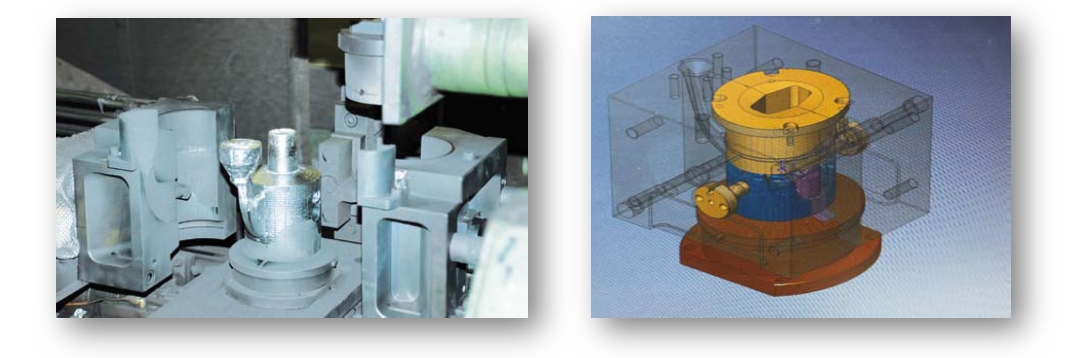

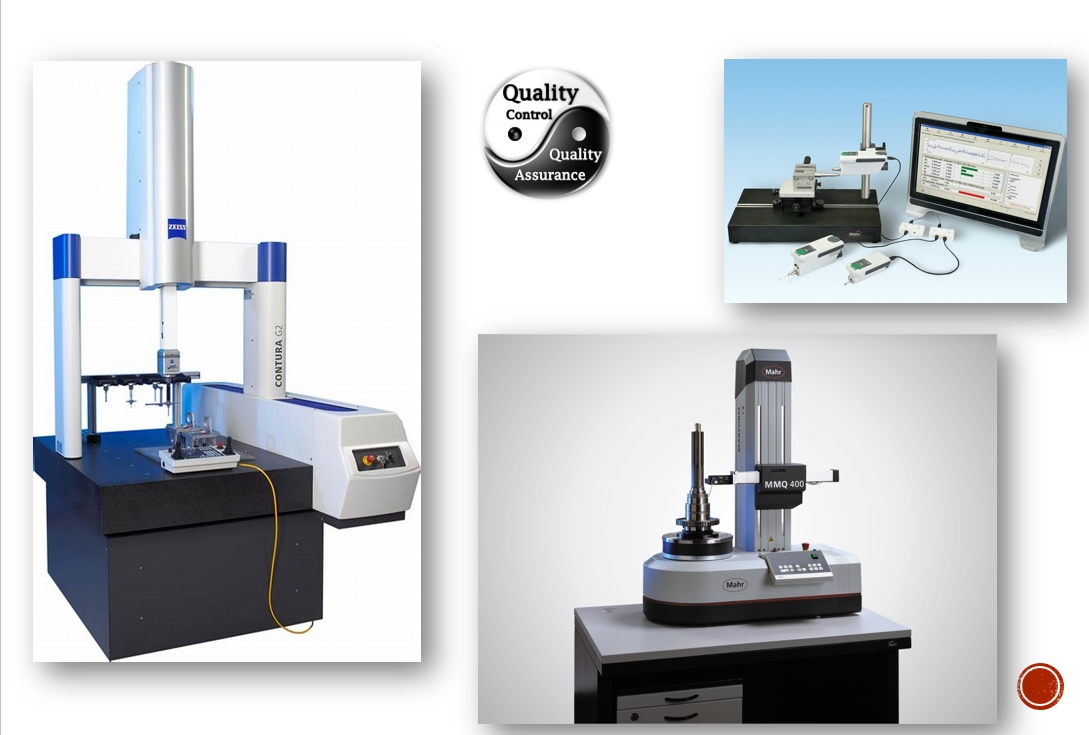

Technical Dept.

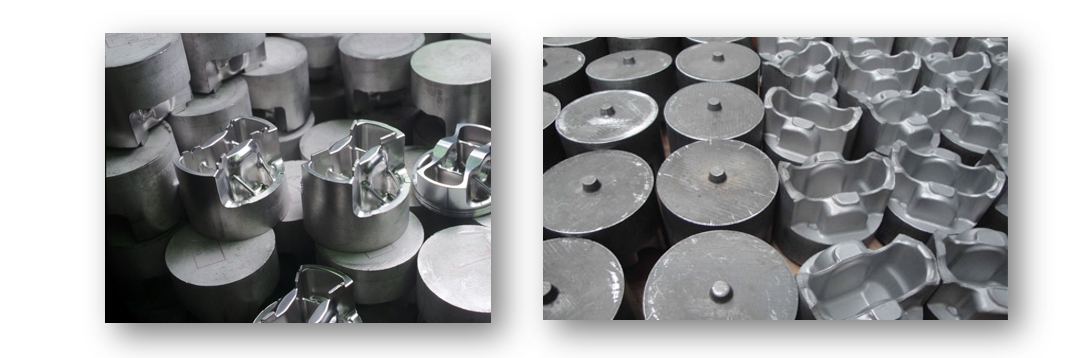

Foundry Shop

Two different processes to produce the blanks:

1.Permanent mould gravity casting (inside)

2.Hot forging (sourced)

Gravity casting

Hot forging

Machining Shop

Pistons are produced following specific processes defined by the application, in years spent by our staff analyzing the cycles together machine tools constructors. All the machines (turning, milling and boring operations) are cnc controlled and CAM connected to office with interaction for programs and quality controls.

.jpg)

English

English Italiano

Italiano.jpg)

WareHouse

WareHouse